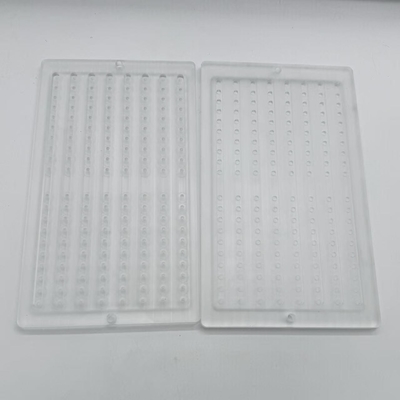

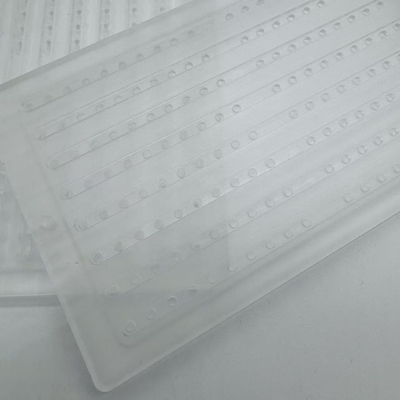

Compared with the limitations of traditional transparent materials - the fragility and heaviness of glass and the roughness and vulnerability of low-quality plastics, PMMA (also known as acrylic) has become an ideal choice for many application fields due to its excellent transparency, superior mechanical properties and good weather resistance. Through precision forming by CNC machining, PMMA parts not only have outstanding structural stability, but also meet the high standards of appearance accuracy and functionality, and are widely used in electronics, medical, optical, industrial and other fields.

►Application fields

PMMA parts are widely used in the following industries:

- Electronics: display screens, touch screens, buttons, housings, optical components, etc.

- Lighting equipment: lamp covers, light guide plates, LED lenses, etc.

- Automotive industry: car lamp covers, instrument panels, interior components, etc.

- Medical devices: observation windows, experimental equipment, disposable medical supplies, etc.

- Architecture and home furnishing: interior decoration, display stands, furniture components, etc.

- Optical instruments: magnifying glasses, camera lens components, etc.

►what we can do

| Machining Processes |

CNC Milling , CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

| Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

| Parts Size |

Milling Parts ( MAX) :Length 1030mm,Width 800mm, Height 750mm.

Turning Parts ( MAX) :Diamter 680mm,Length 750mm.

|

| Tolerance |

0.01mm |

| Sample |

Samples are for free, sample time is 5 days. |

►Capacity of equipment

We are equipped with a complete range of processing equipment, including CNC Machining Centers, 3-axis/4-axis machining centers, CNC Lathes, CNC Turning Centers, etc., all of which are high-precision CNC machines. These machines can meet the efficient cutting requirements for complex structural components. At the same time, we also have auxiliary equipment such as ordinary lathes, milling machines, grinders, drilling machines, tap centers, indexing fixtures, and CNC punching machines, which can cover the entire process from rough machining to precision machining. Some machines are equipped with 8/12 station hydraulic tool towers, which support efficient multi-tool position continuous processing, significantly improving production efficiency and dimensional consistency.

►Quality control

Quality inspection covers a wide range of key indicators from dimensions to appearance. By using a series of highly precise measuring tools, we conduct rigorous control over each finished product from multiple dimensions and in all aspects:

- Measuring Project

- Microscope

- Digital Caliper

- Spiral micrometer

- Altimeter

- Digital height gauge

We offer flexible customized services, supporting both small-batch prototyping and mass production. Based on your specific drawings (supporting formats such as STEP, IGS, DWG, PDF, etc.) and requirements, we can provide a one-stop solution from material selection to precise CNC processing and forming. Standard parts can be delivered within 5-7 days, and expedited delivery can be negotiated.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!