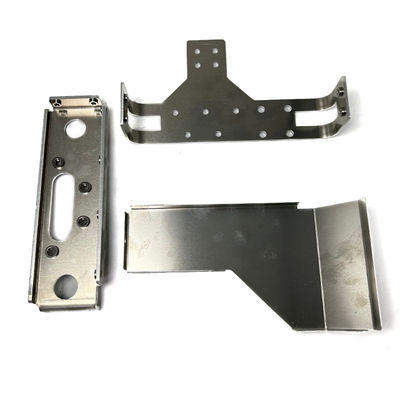

Sheet metal is a comprehensive processing technology that involves shearing, CNC Machining, stamping, bending, welding, assembly and other processes on metal sheets. It is widely used in industries such as automobiles, electronics, electrical appliances and mechanical equipment. Sheet metal processing features high efficiency, low cost and high precision, making it suitable for mass production and customized manufacturing.Common materials include stainless steel, cold-rolled steel plates, aluminum plates, etc., which can be used to make chassis shells, electrical cabinets, sheet metal parts, etc. Sheet metal processing is an indispensable and important link in modern manufacturing industry.Sheet metal is a comprehensive processing technology that involves shearing, CNC Machining, stamping, bending, welding, assembly and other processes on metal sheets. It is widely used in industries such as automobiles, electronics, electrical appliances and mechanical equipment. Sheet metal processing features high efficiency, low cost and high precision, making it suitable for mass production and customized manufacturing.Common materials include stainless steel, cold-rolled steel plates, aluminum plates, etc., which can be used to make chassis shells, electrical cabinets, sheet metal parts, etc. Sheet metal processing is an indispensable and important link in modern manufacturing industry.

►Advantages of bending sheet metal parts:

High structural strength: The right-angle or zigzag structure formed after bending can enhance the rigidity and strength of the parts. The combination of numerical control processing technology can further improve the processing accuracy and consistency.

Reduce welding/assembly processes: By rationally designing the bending structure, the number of connecting parts can be reduced and assembly efficiency can be improved.

Simple appearance: One-piece molding can avoid splicing marks and enhance the product's aesthetic appeal.

| Item |

Reference Parameters |

| Plate Thickness (t) |

0.5mm – 6mm (commonly used) |

| Bending Radius (R) |

Normally ≥ plate thickness (R ≈ t or 1.5t) |

| Bending Angle |

30° – 135°, standard is 90° |

| Minimum Flange Length |

≥ 2 × plate thickness, to avoid deformation |

| V-Groove Width |

Generally 6 – 12 × plate thickness |

| Springback Compensation |

Typically consider 1° – 3° springback |

1.Diversification of material selection

- Machining Matel:Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel

- Machining Plastic:Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM

2.High precision machining

We have established a full-chain equipment system covering CNC machining, traditional craftsmanship and special processing. The core equipment includes: CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers,Bending machine Laser cutting machine,Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch.

3.Diversified surface treatment

- Plating Zinc Color (Machining Steel Parts),

- Anodize Color, Hard Anodize, Hard Anodize

- Electroless Nicke (Machining Aluminum Parts,Machining Stainless Steel Parts,Machining Brass Parts ),

- Passivation (Machining Stainless Steel parts )

- Sand Blasting (Machining Aluminum parts )

- Brushed ( Machining Aluminum parts,Machining Stainless Steel parts ),

- Bluing and Blackening (Machining Steel parts),

- Trivalent Chromium Process(Machining Aluminum parts)

- Welding, brazing, soldering,Centerless Grinding and Burnishing

4. Customized design

According to the customer's drawings or requirements, we provide full-process services from design to production to ensure that the products fully meet your specification requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!