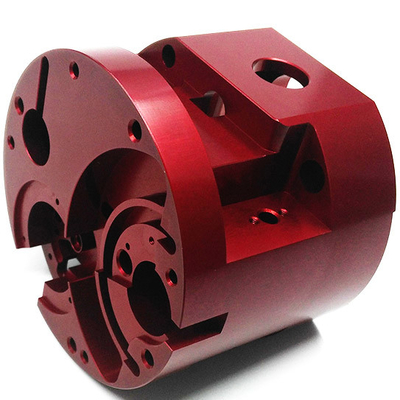

Machining aluminium parts

In terms of machining frequency in the machining industry, machining aluminium parts is only second to steel. Because it has excellent machining performance.The color of aluminium is silver white, ductile and non-magnetic. However, aluminium is usually alloyed with various elements (such as magnesium, manganese, copper, etc.) to form hundreds of aluminum alloys with significantly improved properties,For example:

| Aluminium alloy model |

Mechanical properties |

application area |

| EN AW-6061/3.3211/Al-Mg1SiCu |

High strength alloy With a tensile strength of 180Mpa |

Machine support and aerospace parts. |

| EN AW-6082/3.2315/Al-Si1Mg |

Medium strength, good weldability and thermal conductivity. It has high resistance to stress corrosion cracking |

Building materials, weldable machine supports. |

| EN AW-7075/3.4365/Al-Zn6MgCu |

Higher strength, excellent corrosion resistance and marine environmental performance, close to the strength of steel alloy |

Bicycle frame, UAV, rock climbing equipment, mold manufacturing |

| EN AW 5052/Al-Mg2.5 |

Corrosion resistance, excellent elongation, weldability, good cold workability and medium strength. |

Machine cover, automobile shell, ship shell, sheet metal parts, instruments, and rivets. |

We believe that aluminium is the most Machinable of all metals

Because it is soft and easy to chip, the machining center can cut, drill and turn quickly and accurately. Aluminum is not easy to deform in the process of machining, which will make the machined aluminium parts have higher accuracy.

- Low density and high strength

The density of aluminum alloy is 2.63 ~ 2.85g/cm, which is 1 / 3 of that of steel parts,

High strength( σ B is 110 ~ 650mpa), and the strength of aluminium parts is close to that of steel. It has lighter quality. At the same time, machined aluminum has good corrosion resistance and weldability, and can be used as structural materials. It is widely used in aerospace, aviation, transportation, construction, electromechanical, light and daily necessities.

Although the conductivity of aluminium parts is lower than of copper and steel.

But its lighter weight can make up for the lack of conductivity. Electroless nickel plating on the surface of machined aluminum parts not only increases its hardness, but also increases its conductivity.

After machining aluminium parts, the surface can be brushed and sandblasted. Aluminum anode: aluminum or aluminum alloy parts are used as anodes, which are placed in electrolyte solution, and aluminium oxide film is formed on its surface by electrolysis. The colors of aluminum anodes include natural color, black, red, blue and yellow. At the same time, the hard anode of aluminium parts enhances the surface strength of aluminum parts.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!